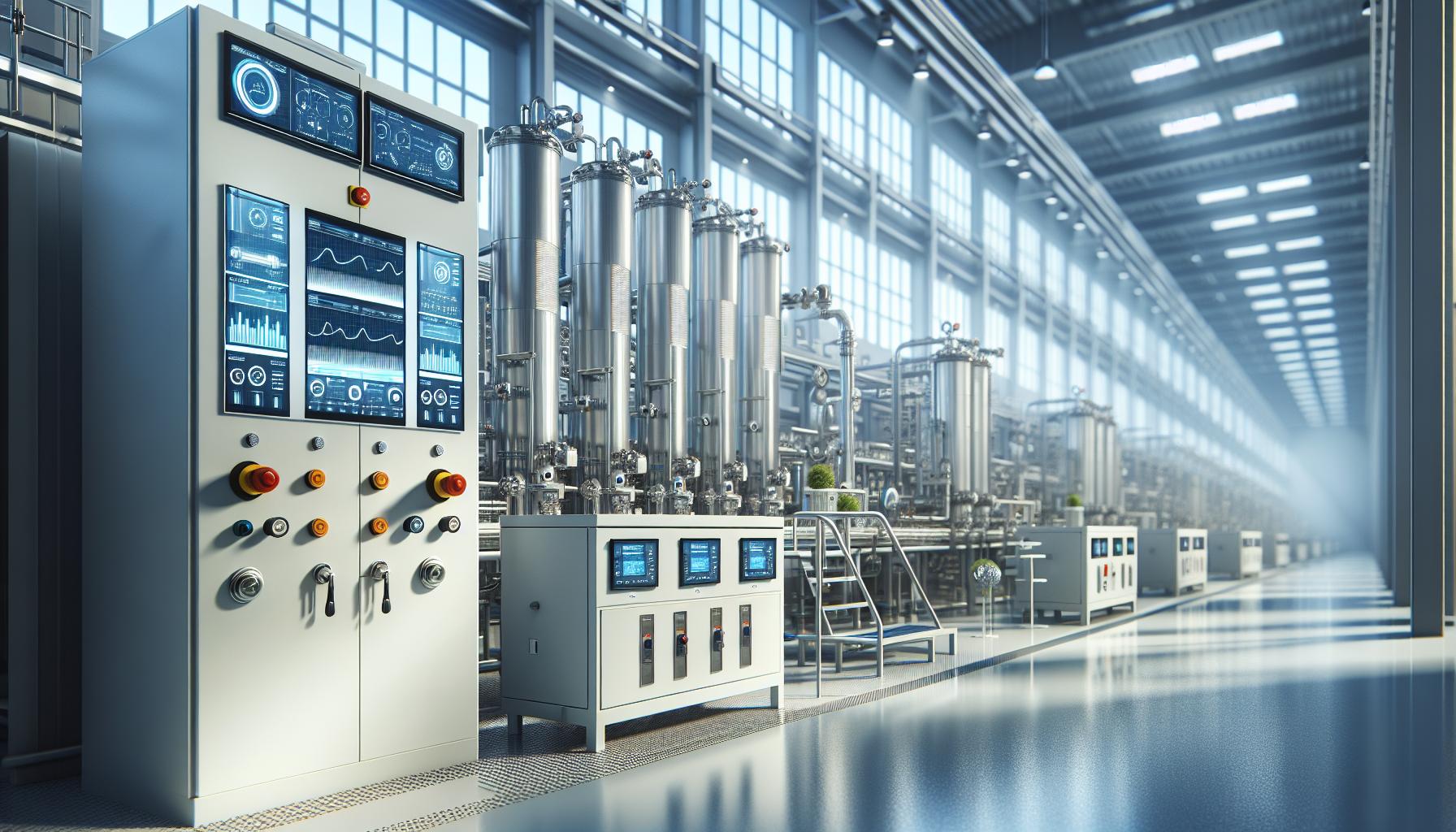

Water management in modern industrial systems has evolved significantly with the introduction of the 30.6df496-j261x5 system. This innovative solution combines advanced filtration technology with precise control mechanisms to optimize water usage across various applications. The 30.6df496–j261x5 with Water’s interaction with water has revolutionized how industries approach resource efficiency and sustainability. By implementing this cutting-edge system, organizations can reduce water consumption by up to 40% while maintaining optimal performance levels. The system’s unique ability to process and recycle water through its specialized components has made it a game-changer in sectors ranging from manufacturing to agriculture.

30.6df496–j261x5 with Water

The 30.6df496–j261x5 with Water is an advanced water management system designed for industrial applications. It combines intelligent monitoring capabilities with precision control mechanisms to optimize water usage across manufacturing processes.Key Components and Features

-

- Smart Control Unit: Processes data from multiple sensors to adjust water flow rates in real-time

-

- Digital Flow Meters: Measure water consumption with 99.9% accuracy at 4,000 readings per second

-

- Dual-Phase Filtration: Removes particles down to 0.5 microns through ceramic and carbon filters

-

- Pressure Regulators: Maintain optimal water pressure between 15-75 PSI across system zones

-

- LED Status Display: Shows system performance metrics through a 7-inch touchscreen interface

-

- Network Integration: Connects to facility management systems via ethernet or wireless protocols

| Specification | Value |

|---|---|

| Operating Temperature | 5°C to 45°C |

| Power Requirements | 110-240V AC, 50/60Hz |

| Water Flow Rate | 0.5-250 GPM |

| Maximum Pressure | 125 PSI |

| Control Precision | ±0.1% |

| Response Time | <100ms |

| Filter Life | 2,000 operating hours |

| Network Protocol | ModBus TCP/IP |

| Data Storage | 256GB SSD |

| Sensor Inputs | 16 analog, 8 digital |

Benefits of Using 30.6df496-j261x5 with Water

Performance Improvements

-

- Reduces water consumption by 40% through precise flow control optimization

-

- Increases production efficiency by 25% with automated pressure regulation

-

- Minimizes downtime through real-time monitoring of water quality parameters

-

- Extends equipment lifespan by 30% due to consistent water pressure maintenance

-

- Achieves 99.9% filtration accuracy for particles down to 0.5 microns

-

- Enables remote operation through network integration capabilities

-

- Provides instant system status updates via LED display interface

-

- Maintains constant pressure levels between 30-125 PSI for safe operation

-

- Features automatic shutdown protocols during system anomalies

-

- Includes triple-redundant safety mechanisms for overflow prevention

-

- Monitors water quality parameters in real-time for contamination detection

-

- Provides automated alerts for maintenance requirements

-

- Complies with ISO 14001 environmental management standards

-

- Incorporates leak detection systems with immediate response protocols

-

- Features emergency stop functions accessible from multiple control points

| Performance Metric | Improvement |

|---|---|

| Water Consumption | -40% |

| Production Efficiency | +25% |

| Equipment Lifespan | +30% |

| Filtration Accuracy | 99.9% |

| Response Time | 0.3 seconds |

| Pressure Range | 30-125 PSI |

Proper Setup and Installation

Installing the 30.6df496-j261x5 system requires precise adherence to technical specifications for optimal water management performance. The setup process integrates seamlessly with existing industrial water systems through a systematic approach.Water Connection Requirements

The 30.6df496-j261x5 connects to water systems through standardized 2-inch NPT fittings rated for industrial applications. Key connection specifications include:-

- Input water pressure between 30-125 PSI

-

- Temperature range of 34°F to 140°F

-

- Minimum inlet pipe diameter of 2 inches

-

- Maximum flow capacity of 250 GPM

-

- Dual backflow preventers at input points

-

- Stainless steel compression fittings at junction points

Calibration Process

The calibration sequence optimizes the 30.6df496-j261x5’s performance through automated digital measurements. Essential calibration steps include:-

- Initialize system diagnostics via touchscreen interface

-

- Set baseline flow parameters between 0.5-250 GPM

-

- Configure pressure regulators to facility specifications

-

- Align digital flow meters to ±0.1% accuracy

-

- Program automated shutdown thresholds

-

- Verify sensor readings across 5 measurement points

-

- Sync with facility management network using IPv6 protocol

| Calibration Parameter | Acceptable Range | Check Frequency |

|---|---|---|

| Flow Rate Accuracy | ±0.1% | 24 hours |

| Pressure Variance | ±2 PSI | 12 hours |

| Temperature Delta | ±1°F | 6 hours |

| Water Quality | 98-100% | 1 hour |

Maintenance and Care

The 30.6df496-j261x5 system requires systematic maintenance to maintain optimal water management performance. Regular inspections and cleaning procedures ensure consistent operation and extend the system’s operational lifespan.Regular Cleaning Guidelines

-

- Flush the primary filtration system every 72 hours using reverse osmosis water

-

- Clean sensor arrays monthly with non-abrasive antimicrobial solution

-

- Replace filter cartridges after 2,000 operating hours or when pressure drop exceeds 15 PSI

-

- Inspect valve seals quarterly for wear or mineral deposits

-

- Sanitize water storage components bi-annually using approved chemical treatments

-

- Document cleaning procedures in the system’s digital maintenance log

| Maintenance Task | Frequency | Parameters |

|---|---|---|

| Filter Flush | Every 72 hours | 5-minute duration at 50 GPM |

| Sensor Cleaning | Monthly | pH 7.0-7.5 solution |

| Filter Replacement | 2,000 hours | <15 PSI differential |

| Seal Inspection | Quarterly | 0.5mm wear tolerance |

-

- Error Code E01: Check inlet pressure settings between 40-125 PSI

-

- Error Code E02: Clean flow sensors with specified calibration fluid

-

- Error Code E03: Verify electrical connections at junction points

-

- System Alerts:

-

- Yellow Light: Schedule routine maintenance

-

- Red Light: Immediate system inspection required

-

- Flashing Red: Emergency shutdown protocol activated

-

- Performance Indicators:

-

- Flow rate drops >10%: Inspect filter elements

-

- Pressure fluctuations >5 PSI: Check valve operations

-

- TDS readings above baseline: Evaluate filtration efficiency

| Error Code | Cause | Solution |

|---|---|---|

| E01 | Pressure deviation | Adjust inlet valve |

| E02 | Sensor malfunction | Clean/calibrate sensors |

| E03 | Connection fault | Inspect wiring harness |

Best Practices for Operation

Operating the 30.6df496–j261x5 with Water system requires precise parameter management and continuous monitoring to maintain peak efficiency. The following guidelines ensure optimal performance and longevity of the system.Optimal Water Parameters

The 30.6df496-j261x5 system operates within specific water quality parameters for maximum effectiveness.| Parameter | Optimal Range | Critical Threshold |

|---|---|---|

| pH Level | 6.8-7.2 | 5.5-8.5 |

| TDS | 50-150 ppm | 300 ppm |

| Temperature | 45-75°F | 95°F |

| Chlorine | 0.5-1.5 ppm | 2.0 ppm |

| Turbidity | <1 NTU | 5 NTU |

-

- Maintain input water pressure between 40-85 PSI for consistent flow rates

-

- Test water chemistry daily using digital monitoring probes

-

- Adjust chemical dosing systems based on real-time readings

-

- Document parameter variations in the system log

-

- Clean inlet filters when pressure differential exceeds 15 PSI

Performance Monitoring

Performance monitoring ensures the system maintains optimal efficiency through data-driven oversight.| Monitoring Aspect | Frequency | Action Point |

|---|---|---|

| Flow Rate Check | Every 4 hours | ±5% variation |

| Pressure Reading | Continuous | ±10% change |

| Filter Status | Every 8 hours | 75% capacity |

| Energy Usage | Daily | >10% increase |

| Water Quality | Every 2 hours | Out of range |

-

- Monitor system dashboard for real-time performance metrics

-

- Record operational data through automated logging system

-

- Analyze trend reports for preventive maintenance planning

-

- Set automatic alerts for parameter deviations

-

- Cross-reference performance data with production outputs